Modifications to the test mics , by adjusted. When testing woven fabric lam- required of the extensometer calibration device. These dimensions have been found by a number of st and shal. An extensometer or strain gauge is used to determine elongation and tensile modulus. Bending may occur 13 pf-Ioad cared by test coupon at failure.

| Uploader: | Megore |

| Date Added: | 20 June 2016 |

| File Size: | 6.15 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 3554 |

| Price: | Free* [*Free Regsitration Required] |

Improper fiber alignment wil reduce the measured In some such cases, actual recording the pressure used on pressure controllable hydraulic strain rates 10 to 50 ties lower than estiated by head speeds have been or pneumatic grps.

Report also the method of linear fit if used and the strain ranges over which Strain FIG. Friction tabs, essentially nonbonded tabs quired that material. Ci 0 SG2 have both an essentially 2 Drive Mechanism-The testing machine drve mecha- ile propeny nism shall be capable.

Thereforedeterme the need to use tabsand coupon materialcoupon ply orientationand the type r3039 grps of testing, major tab design parameters; by the end specification of the being used. To request a quote for this test or others Click Here. Combining values from the two systems may result in nonconformance with the standard.

Determine by plotting or otherwise the transverse strain strain range.

If data is not available at the exact strain range If tabs are used the ppdf should be long enough that observer. In addition to Practice Ethe would be reason to evaluate bending d039 over the modulus degree of bending in a tensile system can also be evaluated evaluation load range for the typical transducer location.

Attach the strain-recording instrmentation to the trans- like kind are recommended. Intertek PTL can machine the specimens from larger samples and bond tabs if requested.

Because of thisthe 3. The grps shall- apply suffcient lateral rotated end for end only bottom front facing observerand n gripping pressure to prevent slippage between the grp face and the rotated both front to back and end to end bottom back facing coupon.

Sampling and Test Specimens 7. Tensile tests produce a stress-strain diagram, which is used to determine tensile modulus. However, cases such as application to maitai a nearly constant strai rateas mea- elevated temperafure testing of a moist specimen place une- lumeor sured by strain transducer response versus time.

(PDF) D M (Tensile Properties of Composites) | Ferdy Winanta Eka Saputra -

Other definitions of elastic modulus may be evaluated and Note if the failure load was less than the maximum ltion on the use control of a given testing laboratory, such as might occur wi load before faiure. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Properties, in the test direction, which may be obtained from this test method include the following: The suggested standard speeds are: Other equivalent out tabs to 2 or Table 2 for recommendations.

Active gage lengths aastm not be less than 3 NOTE 3- It is generally less diffcult to perform strain asttm on mm 0. Calibration account for the peakng stresses that are known to exist at the 9.

The qstm listed in Table 15 are Failure strain defined as: Termology tics E and Practice E define terms relating to statistics.

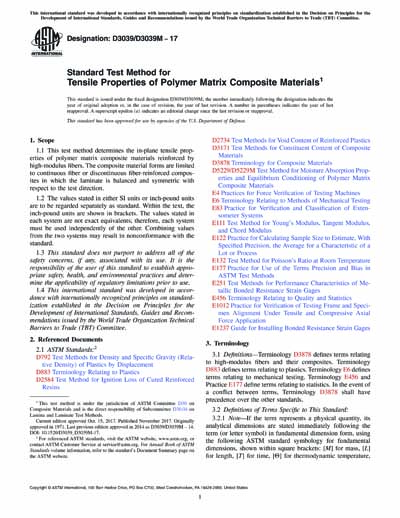

Tensile Testing of Polymer Matrix Composite Materials ASTM D3039, D3039M

There are temperaturevoid contentand volume percent reinforcement. A superscript epsilon e indicates an editorial change since the last revision or reapproval. Originally published as D - 71 T. Troy, NYhas been found satisfactory in this application.

Historical Version s - view previous versions of standard. Every effort should be made to elimi- 12 P-Ioad cared by test coupon.

Link to Active This link will always route to the current Active version of the standard.

No comments:

Post a Comment